| Availability: | |

|---|---|

| Quantity: | |

Product Description

Design&Manufacture | Face to Face | Flange Dimension | Pressure&Temperature | Test & Check |

GB/T12235 | GB/T12221 | JB/T 79 | GB/T12224 | GB/T9092 |

Nominal Pressure | 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 16.0 |

Shell Strength Test | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 | 24.0 |

Bacd Seat Test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 18.0 |

Seat Test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 18.0 |

Technical Parameters

No. | Part Name | Carbon Steel | Alloy Steel | Stainless Steel |

1 | Body | ASTM A216 WCB | ASTM A217-WC9 | ASTM A351 CF8M |

2 | Disc | ASTM A182 F6a | ASTM A182-F22/STL.OVERLAY | ASTM A182 F316 |

3 | Disc Sleeve | ASTM A182 F6a | ASTM A182-F22/STL.OVERLAY | ASTM A182 F316 |

4 | Stem | ASTM A182 F6a | ASTM A182 F6a | ASTM A182 F316 |

5 | Bellow Seal | ASTM A276 304 | ASTM A276 304 | ASTM A276 316 |

6 | Bonnet Gasket | Soft Iron | Soft Steel | ASTM A276 316 |

7 | Bonnet | ASTM A216 WCB | ASTM A217-WC9 | ASTM A351 CF8M |

8 | Bolt | ASTM A193 B7 | ASTM A193 B16 | ASTM A193 B8 |

9 | Nut | ASTM A194 2H | ASTM A194 4 | ASTM A194 8 |

10 | Packing | SS316+Graphile | SS316+Graphile | SS316+Graphile |

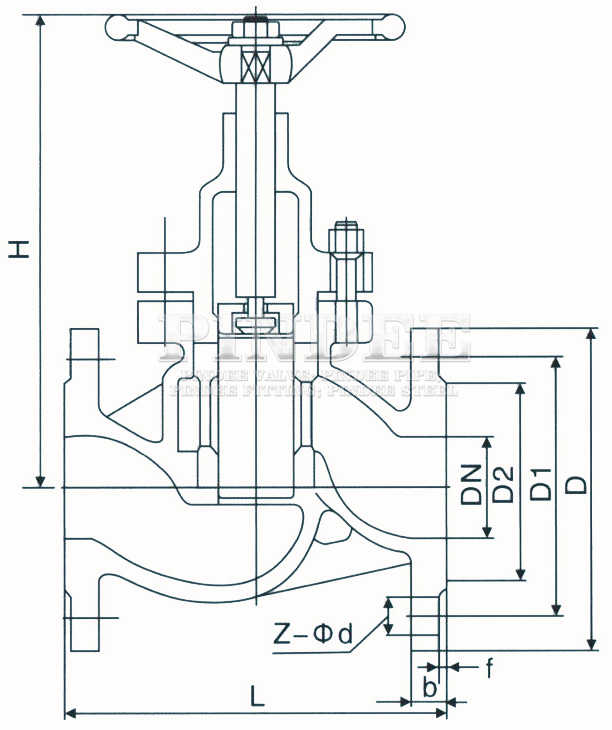

The illustration of design features of cast steel globe valve

Design/Inspection standards: API 6D, API 600, ASME B16.34, BS EN13709, BS 1873, ASME B16.10, ASME B16.5.

(1) Handwheel operated with OS&Y and rising stem.

(2) Gland eyebolts are applied to facilitate packing maintenance and easy dismantling.

(3) Body/Bonnet joint design: male and female matching joint for 150LB~600LB; metallic ring gasket seal for 900LB and above.

(4) T-shaped anti blow-out stem design.

(5) Plug-shaped disc and seating face design allows particular flow characteristic.

(6) Seating surface shall be hardened by stellite 6 overlay.

Pindee Globe Valve Manufacture

Application:

1.Chemical industry;

2.Metallurgy;

3.Power;

4.Paper-making;

5.Pharmacy;

6.Food;

7.Water-treatment.