| Availability: | |

|---|---|

| Quantity: | |

Product Description

General:

Wafer single disc check valve is a crucial component in various industrial applications. It is designed to regulate the flow of fluids by allowing the liquid to flow in one direction and prevent backflow to ensure the safe and efficient operation of piping systems.

This type of check valve has a simple yet effective design that allows it to operate smoothly without compromising the overall system performance. It features a disc that is mounted on a hinge, allowing it to swing open when the fluid flows in one direction and close tightly when the liquid attempts to flow back.

The wafer single disc check valve is easy to install and maintain, making it a popular choice for many industrial applications. Its compact size and lightweight design make it ideal for use in tight spaces, ensuring that the valves can be installed even in areas where access is limited.

The use of high-quality materials in the construction of this check valve ensures that it can withstand harsh operating conditions and corrosion, making it durable and long-lasting. This not only guarantees the reliable operation of the system but also minimizes downtime and maintenance costs.

In conclusion, the wafer single disc check valve plays a critical role in the efficient operation of various industrial applications. Its positive contribution to system performance, ease of installation, and maintenance make it an indispensable component in the industry. Its enhanced reliability and durability make it a valuable investment for any industrial application.

Connection | Wafer end |

Material | Stainless Steel, WCB |

Pressure | 0 to 64 bar |

Medium Temperature | -29 to 300℃ |

Mediums | Water, oil, air, gas, and other mediums |

| Main Part Material | Body | WCB(A105) | ZG1Cr18Ni9Ti | CF8(304) | CF3(304L) | CF3M(316L) |

| Disc | 2Cr13 | 1Cr18Ni9 | oCr18Ni9 | ooCr19Ni10 | ooCr17Ni14Mo2 | |

| Seal ring | 2Cr13 | 1Cr18Ni9 | oCr18Ni9 | ooCr19Ni10 | ooCr17Ni14Mo2 | |

| Spring | oCr18Ni9 | oCr18Ni9 | oCr18Ni9 | ooCr19Ni10 | ooCr17Ni14Mo2 | |

| Applicable condition | Suitable medium | water,vapour,oil | Nitric acid | Strong oxidizing medium | Urea | |

| Suitable temperature | -29℃~425℃ | -196℃~540℃ | -196℃~425℃ | -196℃~455℃ | ||

Techical Parameters

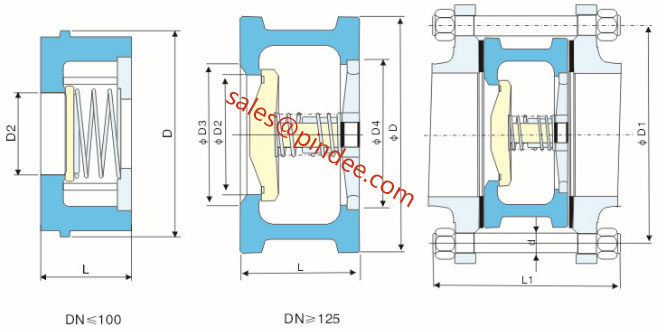

| Pressure Level | DN | Measurement(mm) | Weight(kg) | |||||

| L | D | D2 | D3 | D4 | D5 | |||

| PN10 | 15 | 22 | 52 | 15 | 24 | 31 | 40 | 0.12 |

| 20 | 24 | 62 | 19 | 30 | 40 | 50 | 0.24 | |

| 25 | 28 | 72 | 24 | 36 | 47 | 58 | 0.34 | |

| 32 | 28 | 83 | 31 | 45 | 56 | 68 | 0.53 | |

| 40 | 31.5 | 93 | 39 | 55 | 66 | 78 | 0.8 | |

| 50 | 40 | 108 | 48 | 65 | 78 | 90 | 1.2 | |

| 65 | 46 | 128 | 62 | 80 | 95 | 110 | 1.8 | |

| 80 | 50 | 142 | 76 | 95 | 110 | 128 | 2.2 | |

| 100 | 60 | 162 | 95 | 115 | 135 | 150 | 3.4 | |

| 125 | 90 | 192 | 110 | 125 | 132 | 9 | ||

| 150 | 106 | 218 | 127 | 150 | 158 | 14 | ||

| 200 | 140 | 273 | 165 | 200 | 208 | 24 | ||

| PN16 | 15 | 22 | 52 | 15 | 24 | 31 | 40 | 0.12 |

| 20 | 24 | 62 | 19 | 30 | 40 | 50 | 0.24 | |

| 25 | 28 | 72 | 24 | 36 | 47 | 58 | 0.34 | |

| 32 | 28 | 83 | 31 | 46 | 56 | 68 | 0.53 | |

| 40 | 31.5 | 93 | 39 | 55 | 66 | 78 | 0.8 | |

| 50 | 40 | 108 | 48 | 65 | 78 | 90 | 1.2 | |

| 65 | 46 | 128 | 62 | 80 | 95 | 110 | 1.8 | |

| 80 | 50 | 142 | 76 | 95 | 110 | 128 | 2.2 | |

| 100 | 60 | 162 | 95 | 115 | 135 | 150 | 3.4 | |

| 125 | 90 | 192 | 110 | 125 | 132 | 9 | ||

| 150 | 106 | 218 | 127 | 150 | 158 | 14 | ||

| 200 | 140 | 273 | 165 | 200 | 208 | 24 | ||

| PN25 | 15 | 22 | 52 | 15 | 24 | 31 | 40 | 0.12 |

| 20 | 24 | 62 | 19 | 30 | 40 | 50 | 0.24 | |

| 25 | 28 | 72 | 24 | 36 | 47 | 58 | 0.34 | |

| 32 | 28 | 83 | 31 | 46 | 56 | 68 | 0.53 | |

| 40 | 31.5 | 93 | 39 | 55 | 66 | 78 | 0.8 | |

| 50 | 40 | 108 | 48 | 65 | 78 | 90 | 1.2 | |

| 65 | 46 | 128 | 62 | 80 | 95 | 110 | 1.8 | |

| 80 | 50 | 142 | 76 | 96 | 110 | 128 | 2.2 | |

| 100 | 60 | 168 | 95 | 115 | 135 | 150 | 3.8 | |

| 125 | 90 | 194 | 110 | 125 | 132 | 9.2 | ||

| 150 | 106 | 224 | 127 | 150 | 158 | 15 | ||

| 200 | 140 | 284 | 165 | 200 | 208 | 26 | ||

| PN40 | 15 | 22 | 52 | 15 | 24 | 31 | 40 | 0.12 |

| 20 | 24 | 62 | 19 | 30 | 40 | 50 | 0.24 | |

| 25 | 28 | 72 | 24 | 36 | 47 | 58 | 0.34 | |

| 32 | 28 | 83 | 31 | 46 | 56 | 68 | 0.53 | |

| 40 | 31.5 | 93 | 39 | 55 | 66 | 78 | 0.8 | |

| 50 | 40 | 108 | 48 | 65 | 78 | 90 | 1.2 | |

| 65 | 46 | 128 | 62 | 80 | 95 | 110 | 1.8 | |

| 80 | 50 | 142 | 76 | 96 | 110 | 128 | 2.2 | |

| 100 | 60 | 168 | 95 | 115 | 135 | 150 | 3.8 | |

| 125 | 90 | 194 | 110 | 125 | 132 | 9.2 | ||

| 150 | 106 | 224 | 127 | 150 | 158 | 15 | ||

Pindee Check Valve Manufacture

Application:

1.Suitable for oil;

2.Chemical;

3.Chemical fertilizer;

4.Chemical fertilizer;

5.Power industry and other working conditions of the pipeline.