| Availability: | |

|---|---|

| Quantity: | |

Product Description

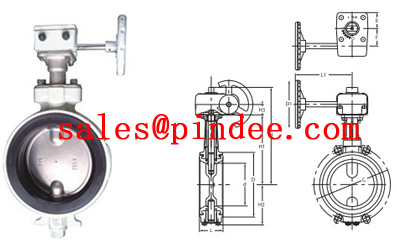

Worm Gear Aluminum Butterfly Valve Manufacture by Pindee Valve,which this kind of Worm Gear Aluminum Butterfly Valve is one of the popular product made in China,welcome our new and regular customer pay a visit to our website and send us an inquiry to us: sales@pindee.com

1. The valve body is made of high-performance aluminum alloy material, which can effectively prevent the temperature difference of the valve body and achieve no condensation on the surface of actuator and flange.

2. The valve body material has low water absorption, corrosion resistance, heat insulation and cold insulation, which is 4 times of the common material.

3. The valve plate is made of 304 material, and its mechanical properties and anti-corrosion properties are up to standard.

4. The rubber of valve seat uses EPDM rubber that meets the standard, which makes the resilience and pulling force of butterfly valve super stable and reliable, and there is no leakage even if it opend or closed more than 10000 times.

5. PE heat shrinkable plastic packaging technology are used in product packaging. Each Bundor product is individually packed with heat shrinkable film and built-in desiccant, which isolates air dust and helps to store and avoid product corrosion caused by moisture.

Applicable medium:Clear water, sewage, sea water, weak acid and alkali, air, steam, etc

Suitable temperature:0~80℃

Application field:Municipal construction, water conservancy engineering, electric power, water supply and drainage, water treatment, etc

Technical Parameter:

| Name | Design and manufacture | Structural length | Pressure-Testing Standards | Upper flange size | ||||||||

| Reference standard | JIS B2032 | JIS B2002 | GB/T 13927-2008 | ISO 5211 | ||||||||

| Name | Body | Seat | Disc | Stem | Worm gear | |||||||

| Material | Aluminium alloy | NBR/EPDM | 304/316 | 416/304/316 | Composite member | |||||||

| Caliber | d | L | Z | H1 | H2 | H3 | L1 | L2 | L3 | D1 | Weight/kg | |

| DN50 | 2" | 52 | 43 | 101.3 | 65 | 130 | 157 | 43.5 | 45 | 67 | 120 | 2.15 |

| DN65 | 2.5" | 67 | 46 | 121 | 75 | 140 | 167 | 43.5 | 45 | 67 | 120 | 2.55 |

| DN80 | 3" | 81.5 | 46 | 130.7 | 83 | 153 | 180 | 43.5 | 45 | 67 | 120 | 2.65 |

| DN100 | 4" | 103 | 52 | 156 | 97 | 168 | 196 | 43.5 | 45 | 67 | 120 | 3.15 |

| DN125 | 5" | 125 | 56 | 185.9 | 119 | 203 | 231 | 43.5 | 45 | 67 | 120 | 4.95 |

| DN150 | 6" | 149 | 59 | 218 | 134 | 215 | 243 | 43.5 | 45 | 67 | 120 | 5.9 |

| DN200 | 8" | 199 | 60 | 267 | 170 | 246 | 273 | 52 | 46 | 75 | 160 | 8.5 |

| DN250 | 10" | 248 | 68 | 315 | 214 | 330 | 370 | 67 | 81 | 99 | 250 | 18.35 |

| DN300 | 12" | 298 | 78 | 364 | 251 | 358 | 398 | 67 | 81 | 99 | 250 | 22.8 |

Pindee Valve Manufacture

Pindee Valve Inspection:

Pindee Valve Packing:

Application:

Municipal construction, water conservancy engineering, electric power, water supply and drainage, water treatment, etc