| Availability: | |

|---|---|

| Quantity: | |

Product Description

Soft-Back Seat Lug Butterfly Valve Manufacture by Pindee Valve,which this kind of Soft-Back Seat Lug Butterfly Valve is very popular in Asia,Europe, North American, South American,welcome our new and regular customers pay a visit to our website and send us an inquiry to see our price and delivery time.Our sales Manager email: sales@pindee.com

The dovetail replaceable soft back seat of the China lug butterfly valve refers to the fully lug wafer butterfly valve with the EPDM soft seat, which can be replaced. This can reduce the cost when the seat is broken.

Excellent sealing and chemical resistance: EPDM valve seat has high elasticity and resilience, so it can effectively seal the valve and prevent leakage. Besides, it has excellent chemical stability, can resist corrosion and erosion from a variety of chemicals, and is suitable for various media.

Temperature adaptability: EPDM valve seats can work normally in a wide temperature range, with good heat resistance and cold resistance from minus 20 to 80 degrees Celsius.

Lug design: Lug butterfly valve has a lug design. It can reduce the erosion of the valve seat and sealing ring by the medium, and improve the service life and reliability.

Centerline design: This lug butterfly valve adopts a centerline design, which makes the valve action more stable and accurate, reduces the opening and closing torque, and improves operating performance and ease of use.

The origin of the Lug butterfly valve is China.

| Parts | Ductile Iron type | WCB type | Stainless Steel Type | Duplex Stainless Steel Type |

| Body | Cast Iron(GG25) | A216 | SS304/ CF8 | 2205 |

| Ductile Iron(GGG40/50) | A217 | SS316/CF8M | 2507 | |

| A105(forged) | SS304L/CF3 | 1.4529 | ||

| SS316L/CF3M | ||||

| Disc | Ductile Iron with Ni coated | SS304/ CF8 | 2205 | |

| Ductile Iron with nylon coated | SS316/CF8M | 2507 | ||

| Ductile Iron with PTFE/EPDM lined | SS304L/CF3 | 1.4529 | ||

| Stainless Steel | SS316L/CF3M | |||

| Duplex Stainless Steel | 2205 | |||

| Bronze | 2507 | |||

| 1.4529 | ||||

| Seat | NBR, EPDM, PTFE, Viton, Hypalon, Silicon, PFA | |||

| Stem | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel | Duplex Stainless Steel, Monel | ||

| Actuator | Hand Lever, Worm Gear, Electric, Pneumatic | |||

Technical Parameter:

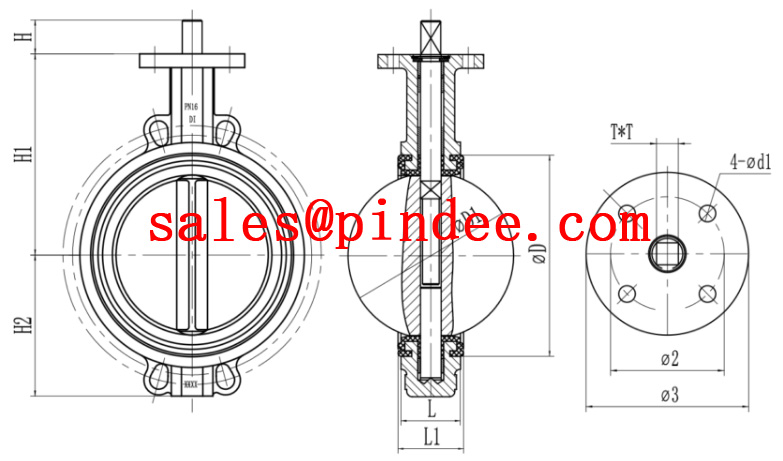

| SIZE | øD | øD1 | L | L1 | H | H1 | H2 | ø2 | ø3 | 4-ød1 | T*T |

| DN25 | 55 | 33 | 26 | 29 | 30 | 122 | 48 | 50 | 65 | 7 | 11 |

| DN40 | 65 | 43.1 | 33 | 36 | 30 | 139 | 70 | 50 | 65 | 7 | 11 |

| DN50 | 82 | 53.08 | 42.5 | 46.1 | 30 | 140 | 60 | 70 | 90 | 10 | 11 |

| DN65 | 94 | 64.82 | 45.6 | 49 | 30 | 150 | 67 | 70 | 90 | 10 | 11 |

| DN80 | 111.2 | 79.04 | 45.6 | 48.4 | 30 | 160 | 87 | 70 | 90 | 10 | 11 |

| DN100 | 140 | 104.04 | 52 | 56 | 30 | 180 | 105 | 70 | 90 | 10 | 11 |

| DN125 | 166 | 123.3 | 56 | 60 | 30 | 190 | 118 | 70 | 90 | 10 | 14 |

| DN150 | 187 | 155.68 | 56 | 60 | 30 | 210 | 130 | 70 | 90 | 10 | 14 |

| DN200 | 246.8 | 201.9 | 60 | 64 | 35 | 235 | 166 | 102 | 125 | 12 | 17 |

| DN250 | 301.5 | 250.45 | 68 | 72 | 35 | 270 | 197 | 102 | 125 | 12 | 22 |

| DN300 | 352 | 301.55 | 78 | 83 | 35 | 305 | 231 | 102 | 125 | 12 | 22 |

| DN350 | 390 | 333.8 | 78 | 83 | 35 | 360 | 255 | 125 | 150 | 14 | 22 |

| DN400 | 452 | 389 | 102 | 106 | 50 | 381 | 293 | 140 | 175 | 18 | 27 |

| DN450 | 510 | 439.2 | 114 | 118 | 50 | 425 | 325 | 140 | 175 | 18 | 27 |

| DN500 | 564 | 491.4 | 127 | 132 | 50 | 470 | 363 | 140 | 175 | 18 | 36 |

| DN600 | 651 | 579 | 153 | 159 | 60 | 565 | 425 | 165 | 210 | 22 | 36 |

Pindee Valve Manufacture

Application:

Water Treatment Plant ;2.Drilling Rigs;3.Paper Industry;4.Gas Plant;5.Sugar Industry;6.Cooling Water Circulation;7.Breweries;8.Heating & Air Conditioning;9.Chemical Industry;10.Pneumatic Conveyors;11.Waste Effluent Treatment Plant ;12.Compressed Air.

Pindee Valve Inspection:

Pindee Valve Packing: